Stone is Over. It's Porcelain's Time to Shine.

If there’s one material that’s dominated the outdoor DIY and home improvement conversation over the past decade or so, it’s stone. And while it boasts many desirable qualities as a flagging material (great natural look, robustness, durability), the problem with stone’s popularity is that it has eclipsed some great alternatives from public view. So if stone’s spell at the top of the flag pile is over, which material will take up its mantle? Our money is on porcelain as a rock-solid alternative to natural stone. Here’s why...

A natural, long-lasting look

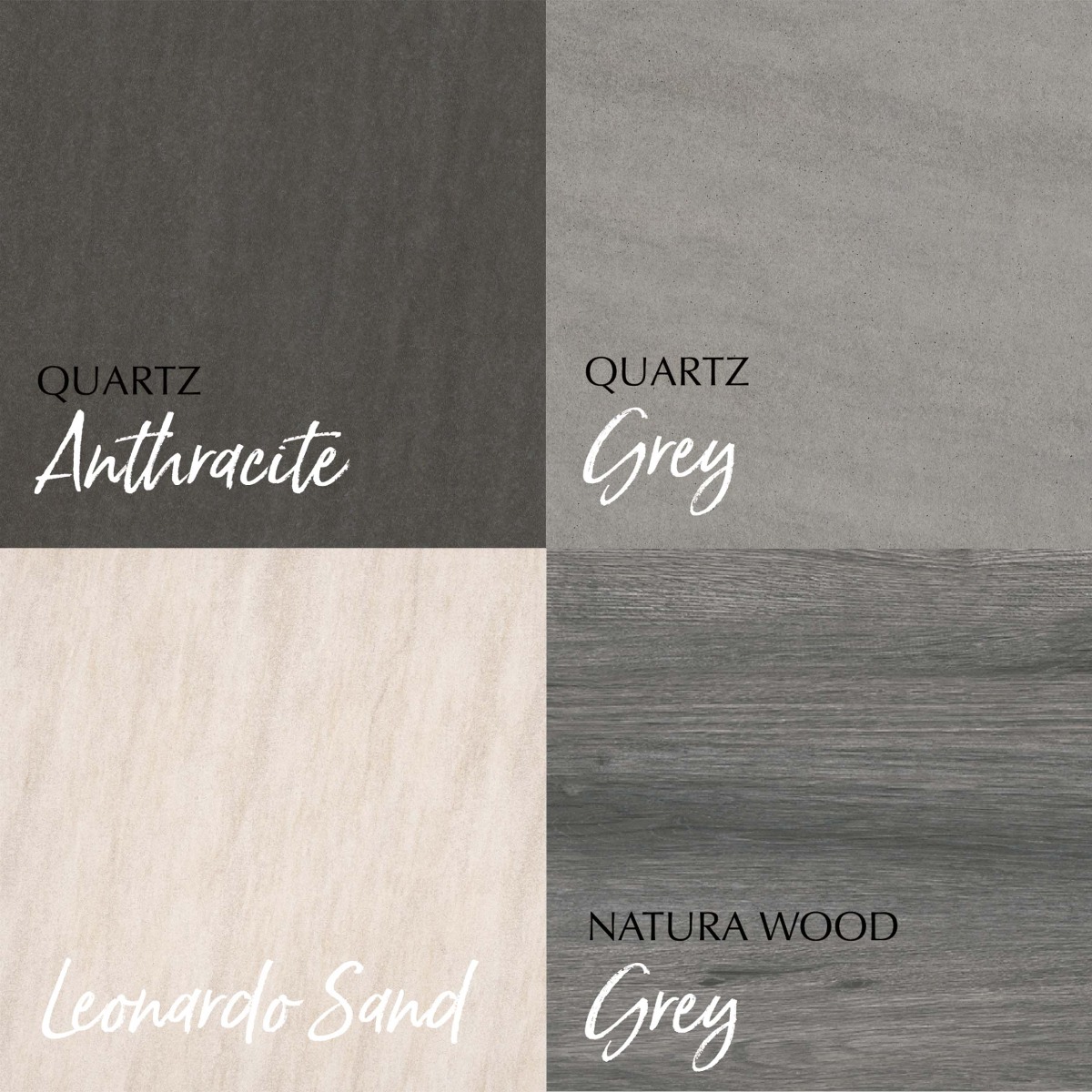

Although porcelain is man-made, it is still created from natural materials. This means it retains some of stone’s natural charm, colour variation, veining, and fossilisation. However, porcelain benefits from being more flexible than natural stone as it can be manufactured into a wide variety of shapes and sizes. Porcelain tiles are also UV-resistant, minimising the amount of colour fading over time; cooked at around 1200 degrees celsius, the porcelain baking process essentially “locks in” the pigmentation of each individual tile.

Durable and flexible

Until relatively recently, porcelain was only manufactured in 9 to 12mm profiles. This made it an unsuitable material for many applications - like outdoor tiling - due to its thin profile. However, advances in technology mean porcelain can now be manufactured in slabs of 20mm+ thickness. In this sturdier format, porcelain is now enjoying a growing reputation as a viable option for outdoor paving. Porcelain is treated to resist changeable weather conditions (severe temperature changes, frost, and cold snaps) as well as erosion from general weathering. That same treatment process also protects porcelain from acidity, chemicals, salts, and oils - making it a great option for both industrial and domestic settings.

Scratch proof, easy to clean

As porcelain is fully treated during the manufacturing stage, it requires no additional treatments like sealants to be applied before installation. And thanks to its low porosity level (below 0.05%) porcelain does not absorb water. That means porcelain tiles require only a mild detergent to keep them looking spotless. While footwear and outdoor furniture can leave temporary marks, these can easily be wiped away with no long-term scratching or damage to the tiles’ surface. And with just a simple jet wash once a year, porcelain tiles will stay looking new for decades.

Easy to install

Porcelain tiles are exceptionally easy to install. Usually, they are laid using traditional techniques. That means no specialist skills, equipment, or materials are required to install them - a DIY dream.

Safety

Porcelain is manufactured with a range of anti-slip textured surfaces, marked on a scale of 1 to 5. And thanks to its low-porosity, water stays on the surface, evaporating very quickly, making the risk of slips minimal. This makes them especially safe and practical for outdoor applications in wet

climates.

Cost

If there’s one area where porcelain comes into its own as a material, it’s its comparative affordability; some natural stone paving materials are among the most expensive available. Porcelain, on the other hand, can be manufactured in a cost-effective fashion, keeping its retail prices down - great news if you have a few hundred square feet of outdoor space to pave. The savings offered by porcelain also extend to the installation phase of your project. Unlike natural stone materials, porcelain does not require pre-sealing and requires much thinner adhesives as there are no irregular bumps in the tiles’ surface. Ready to embrace the future of outdoor tiling?

Click here to check out our new range of porcelain tiles.